Shaping Dreams, One Layer at a Time

Welcome to the Future of Creation, where Imagination Meets Innovation through Additive Manufacturing.

Your Gateway to On-Demand 3D Printing Excellence

Layer Height

The layer height determines the resolution of your print. Smaller layer heights result in finer details but may increase print time.

3D Printing Material

The type of filament you use impacts the properties of your final print. Factors to consider include material strength, flexibility, durability, and post-processing requirements.

Embark on your 3D Printing Zen

Fast, Simple Ordering with Instant Quotes in Minutes

| Upload STL |

| Configure 3D Print |

| Get Instant Quote |

| Order |

| Processing |

| QC |

| Shipping |

Cornerstones of exceptional design

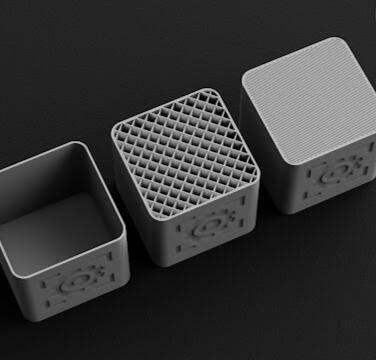

Infill Percent

Infill percentage controls the balance between strength, weight, and material use. Low infill (10-20%) suits lightweight parts, while high infill (60-80%) boosts durability for functional designs.

Infill Types

Infill patterns like Grid, Honeycomb, Gyroid, and Concentric offer flexibility in design. Choose Grid for balanced strength, Honeycomb for lightweight rigidity, or Gyroid for optimal strength and flexibility, tailoring prints to your specific needs.